Sunday, March 28, 2021

Wednesday, November 28, 2018

well, hmmm.

Many times, in recent months, I have thought "I should take a photo and put that on the blog."

Clearly, thinking is not doing. Something I have said over and over to people wanting to weave! You have to just jump in and do it.

So herewith, the last few months:

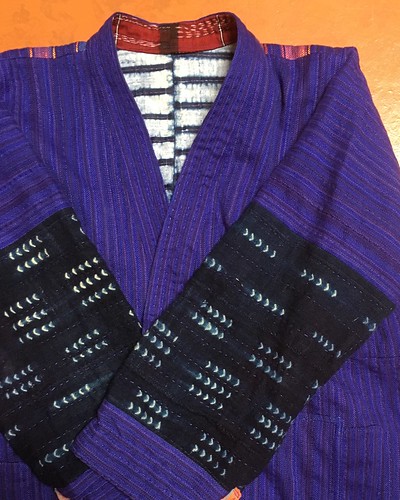

Handspun muga silk fabric, for a kimono, made and worn at Convergence in Reno:

This is the fabric for the body of the garment, and here is the band of the jacket on the loom:

I love that it "goes with" but is not the same. I think both are sett at 48, I'd have to check my notes, but that is somewhat standard, for me, using my handspun silk. No actual photo of the finished garment, and this is what tends to stop me posting at all: should I post what I have, or wait until I have it all? You see the issue. Today? I will post what I have!

Next up:

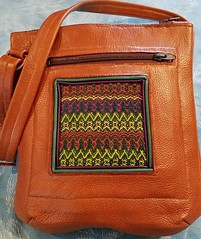

A leather bag made for my friend Eileen, using her fabric as the pocket patch. I am definitely getting better at this leather stuff, practice does make...better? But! I did have to rip out and fix a bag I made for myself:

This is the first iteration: bison leather bag body, and elk leather for the pocket, with a little western sunset in handspun silk on the pocket. The lighter color pocket was a little jarring, to my eyes, despite the good intention of using "western" leathers for a western sky. I used the bag for a few months, until and at last, I realized the lighter color leather was also too thin and floppy to be a pocket. My keys, sunglasses and phone dragged the pocket down and made it look like a deflated balloon, to put it politely. And who wants to carry that around?

So I remade the pocket. I took off the old pocket (which leaves holes in the leather), and stitched the silk patch onto bison leather, added a zipper and then stitched the whole thing over the perforations made by the original pocket. I love love love the stitch pattern on the new iteration! It's a good size pocket, big enough for my phone, and in a pinch, a few other things. But being flat, it is not as good for keys, sunglasses...oh well!

I still totally love it. Since this was made bass-ackwards, so to speak, I will try another using this stitch and another shaped pocket on the front of a bag, done in the proper order, to avoid the holes that this pocket hides.

Just to make this post really long, I'll include one of my recent fabrics:

This is a tweed silk yarn I purchased from another weaver. It makes The.Most.Fabulous.Fabric! This is dip dyed in indigo, and is the top of a blanket. The top is in the process of being stitched to another layer of this silk, the lining/backing or whatever:

Both fabrics are 15/2 silk tweed yarn, sett at 30 epi, woven with 20/2 cotton. I am not a quilter, so I am winging it, just stitching the two layers together with a running stitch, in hopes that it will feel like the whole cloth quilts I like so much. Again, no photo of the whole thing, that will (may?) come later. The stitching will take me months, but is a pleasant contemplative activity:

When I am done with it? A double layer silk blanket. What a treat! The thing weighs at least 4 pounds, too, so it will double as one of those anxiety blankets! And given the current state of affairs in this world, I may need it...

There are a few more things I could post/talk about, but I'll leave this here for now, and make an effort to come back soon with more photos, and more projects. Thanks for listening! and thanks to those of you who have asked where I've been.

Clearly, thinking is not doing. Something I have said over and over to people wanting to weave! You have to just jump in and do it.

So herewith, the last few months:

Handspun muga silk fabric, for a kimono, made and worn at Convergence in Reno:

This is the fabric for the body of the garment, and here is the band of the jacket on the loom:

I love that it "goes with" but is not the same. I think both are sett at 48, I'd have to check my notes, but that is somewhat standard, for me, using my handspun silk. No actual photo of the finished garment, and this is what tends to stop me posting at all: should I post what I have, or wait until I have it all? You see the issue. Today? I will post what I have!

Next up:

A leather bag made for my friend Eileen, using her fabric as the pocket patch. I am definitely getting better at this leather stuff, practice does make...better? But! I did have to rip out and fix a bag I made for myself:

This is the first iteration: bison leather bag body, and elk leather for the pocket, with a little western sunset in handspun silk on the pocket. The lighter color pocket was a little jarring, to my eyes, despite the good intention of using "western" leathers for a western sky. I used the bag for a few months, until and at last, I realized the lighter color leather was also too thin and floppy to be a pocket. My keys, sunglasses and phone dragged the pocket down and made it look like a deflated balloon, to put it politely. And who wants to carry that around?

So I remade the pocket. I took off the old pocket (which leaves holes in the leather), and stitched the silk patch onto bison leather, added a zipper and then stitched the whole thing over the perforations made by the original pocket. I love love love the stitch pattern on the new iteration! It's a good size pocket, big enough for my phone, and in a pinch, a few other things. But being flat, it is not as good for keys, sunglasses...oh well!

I still totally love it. Since this was made bass-ackwards, so to speak, I will try another using this stitch and another shaped pocket on the front of a bag, done in the proper order, to avoid the holes that this pocket hides.

Just to make this post really long, I'll include one of my recent fabrics:

This is a tweed silk yarn I purchased from another weaver. It makes The.Most.Fabulous.Fabric! This is dip dyed in indigo, and is the top of a blanket. The top is in the process of being stitched to another layer of this silk, the lining/backing or whatever:

Both fabrics are 15/2 silk tweed yarn, sett at 30 epi, woven with 20/2 cotton. I am not a quilter, so I am winging it, just stitching the two layers together with a running stitch, in hopes that it will feel like the whole cloth quilts I like so much. Again, no photo of the whole thing, that will (may?) come later. The stitching will take me months, but is a pleasant contemplative activity:

When I am done with it? A double layer silk blanket. What a treat! The thing weighs at least 4 pounds, too, so it will double as one of those anxiety blankets! And given the current state of affairs in this world, I may need it...

There are a few more things I could post/talk about, but I'll leave this here for now, and make an effort to come back soon with more photos, and more projects. Thanks for listening! and thanks to those of you who have asked where I've been.

Friday, April 20, 2018

A Tale of Two Coats

I've had the Turkish Coat pattern from Folkwear for, oh, maybe 35 years. Chatting with some other weavers it seemed it was about time to actually make one up. And what does one do when making a pattern up for the first time? Weave a lot of fabrics:

This is cotton, two lengths of striped fabric, one `11" wide x 12 yards, the other 8" wide x 8 yards, for the outer fabric in the coat. I came to these measurements by laying out the pattern pieces and measuring the finished length and width I would need for the out shell of the coat.

The painted warp fabric is for the back panel of the coat, and the narrow orange fabric is for trim.

I wove, washed, pressed, measured and cut out the coat. The directions call for stitching the layers together as pieces, and then sewing them all together into the final coat, and added the trim at the hem, cuffs, and front border. For this first version (the "muslin") I followed the directions.

These are the sections being stitched along the stripes (handy to have stripe-lines to follow!) to the lining, a resist dyed indigo cotton I purchased at the Santa Fe International Folk Art Market a few years ago. It was somewhat of a pain to sew together all the stitched parts, and then stitch down all the inside seams, but the process was managed. I needed a bit more cloth for the sleeves, so I added some indigo-dyed strip woven Dogon cloth, and the inside fabric of the bands is a Guatemalan jaspe fabric, so in the end, I managed to make a World Coat for the first version:

I'm quite happy with it, it fits and is comfortable, I like the look of it well enough, but...I could see that a few changes might make a coat I would like better! Thus began Turkish Coat 2.0. This one would be silk, all commercial yarns, not handspun, because I wanted to quickly implement the changes while they were fresh in my mind, not wait two years to spin all the yarn.

I changed the width and length of the outer fabric, one 11" again x 12 yards, but the second would be 4" x 12 yards: less waste, more use of selvedges in the final garment. I wove a striped outer layer, in black, and a bright lining an reds. I wove a back panel in painted warp, and some bright interior bands fabrics for the inside. In all, I wove 49+ yards of silk fabric, much of it very narrow, so it wove up quickly. This is the lining, 30/2 silk sett at 48 EPI:

This is the painted warp silk for the back panel (the outside fabric is 12/2 silk sett at 30):

This coat was sewn differently: I basically sewed up the outside shell, and the lining separately, then put the lining inside and stitched the layers together. The hem bands, front bands and cuffs were sewn on last, and then they were stitched too:

I like this coat a lot, and it was much easier to make, despite having the Whole Coat to haul around while stitching the two layers together. Silk is heavy, this thing is all silk and very heavy, but kinda worth it:

For those of you coming to Convergence in Reno this summer, this coat will be my entry in the Leader exhibit, so you'll be able to see it up close and in real life. I will be teaching knotted pile, nothing to do with this coat at all! But there you have it, the coat will represent me anyway.

I am not thrilled with how I pieced the back panel, but I can live with it:

Both coats have a pieced back panel and neither is to my liking, they just did not add that much to the overall look. Maybe next time no piecing?

Next time! There is the issue. Now that I have done one in cotton, and one in silk, I am planning the next version (of who knows how many?) This is how a series begins! One things leads to another, without initial intent I now have a new direction. The Next One will be handspun. Polwarth Silk wool awaits spinning for the outer fabrics, and a handspun silk lining. It will take me at least a year to spin, dye and weave the fabrics. I will follow the plan from T.Coat 2.0 for length and width of the panels to be woven, there will be stripes, because they make great stitching lines, and I think I will stick to the more subtle outside and wildly bright inside plan of the second coat.

Check back this time next year :). This is how an obsession begins.

This is cotton, two lengths of striped fabric, one `11" wide x 12 yards, the other 8" wide x 8 yards, for the outer fabric in the coat. I came to these measurements by laying out the pattern pieces and measuring the finished length and width I would need for the out shell of the coat.

The painted warp fabric is for the back panel of the coat, and the narrow orange fabric is for trim.

I wove, washed, pressed, measured and cut out the coat. The directions call for stitching the layers together as pieces, and then sewing them all together into the final coat, and added the trim at the hem, cuffs, and front border. For this first version (the "muslin") I followed the directions.

These are the sections being stitched along the stripes (handy to have stripe-lines to follow!) to the lining, a resist dyed indigo cotton I purchased at the Santa Fe International Folk Art Market a few years ago. It was somewhat of a pain to sew together all the stitched parts, and then stitch down all the inside seams, but the process was managed. I needed a bit more cloth for the sleeves, so I added some indigo-dyed strip woven Dogon cloth, and the inside fabric of the bands is a Guatemalan jaspe fabric, so in the end, I managed to make a World Coat for the first version:

I'm quite happy with it, it fits and is comfortable, I like the look of it well enough, but...I could see that a few changes might make a coat I would like better! Thus began Turkish Coat 2.0. This one would be silk, all commercial yarns, not handspun, because I wanted to quickly implement the changes while they were fresh in my mind, not wait two years to spin all the yarn.

I changed the width and length of the outer fabric, one 11" again x 12 yards, but the second would be 4" x 12 yards: less waste, more use of selvedges in the final garment. I wove a striped outer layer, in black, and a bright lining an reds. I wove a back panel in painted warp, and some bright interior bands fabrics for the inside. In all, I wove 49+ yards of silk fabric, much of it very narrow, so it wove up quickly. This is the lining, 30/2 silk sett at 48 EPI:

This is the painted warp silk for the back panel (the outside fabric is 12/2 silk sett at 30):

This coat was sewn differently: I basically sewed up the outside shell, and the lining separately, then put the lining inside and stitched the layers together. The hem bands, front bands and cuffs were sewn on last, and then they were stitched too:

I like this coat a lot, and it was much easier to make, despite having the Whole Coat to haul around while stitching the two layers together. Silk is heavy, this thing is all silk and very heavy, but kinda worth it:

For those of you coming to Convergence in Reno this summer, this coat will be my entry in the Leader exhibit, so you'll be able to see it up close and in real life. I will be teaching knotted pile, nothing to do with this coat at all! But there you have it, the coat will represent me anyway.

I am not thrilled with how I pieced the back panel, but I can live with it:

Both coats have a pieced back panel and neither is to my liking, they just did not add that much to the overall look. Maybe next time no piecing?

Next time! There is the issue. Now that I have done one in cotton, and one in silk, I am planning the next version (of who knows how many?) This is how a series begins! One things leads to another, without initial intent I now have a new direction. The Next One will be handspun. Polwarth Silk wool awaits spinning for the outer fabrics, and a handspun silk lining. It will take me at least a year to spin, dye and weave the fabrics. I will follow the plan from T.Coat 2.0 for length and width of the panels to be woven, there will be stripes, because they make great stitching lines, and I think I will stick to the more subtle outside and wildly bright inside plan of the second coat.

Check back this time next year :). This is how an obsession begins.

Friday, March 09, 2018

"Gang Aft A-Gley"

I planned a silk fabric for clothing in black and white stripes: 30's/2 silk sett at 48 EPI. I have lots of cones of silk, all white, which means I will have to dye the black.

I ran the warps, washed them, and set up the dyepot with a 3% solution of black dye. I entered the warps, and here begins the "awry".

The dyepot looked terribly black. It needed just a bit of red, just a bit, which I had on hand, all mixed up. So I dumped some red dye in. That's better! And so, the "black" warps are a nice dark red:

But... herein lies the rub: now it is no longer a "black and white" fabric. Might as well dye the rest:

The "warps formerly known as black" are at the top in this photo, and the rest are various colors. The warp will still be striped, just not black and white. There is a "little" white though, in the resist areas of one small warp.

Maybe there should be a little black too?

Look! I managed to dye actual black! It can still be my "black and white" fabric. It just tripped and fell into some color:

Some things do go as actually planned:

The minute I saw this silk band, woven by John Mullarkey, I knew how this bag would look.

I had the grey and yellow leather on hand, I knew the shape, a little lunchbox, would be perfect to showcase the band and make for a useful project bag, or storage box, and lo, everything managed to fall into place: the bag is exactly how I imagined it!

Practice is paying off. Getting to mastery is not a straight line, and I am quite sure there will be a few face-plants still left in my future, but the satisfaction of making something exactly as envisioned? Priceless!

I ran the warps, washed them, and set up the dyepot with a 3% solution of black dye. I entered the warps, and here begins the "awry".

The dyepot looked terribly black. It needed just a bit of red, just a bit, which I had on hand, all mixed up. So I dumped some red dye in. That's better! And so, the "black" warps are a nice dark red:

But... herein lies the rub: now it is no longer a "black and white" fabric. Might as well dye the rest:

The "warps formerly known as black" are at the top in this photo, and the rest are various colors. The warp will still be striped, just not black and white. There is a "little" white though, in the resist areas of one small warp.

Maybe there should be a little black too?

Look! I managed to dye actual black! It can still be my "black and white" fabric. It just tripped and fell into some color:

Some things do go as actually planned:

The minute I saw this silk band, woven by John Mullarkey, I knew how this bag would look.

I had the grey and yellow leather on hand, I knew the shape, a little lunchbox, would be perfect to showcase the band and make for a useful project bag, or storage box, and lo, everything managed to fall into place: the bag is exactly how I imagined it!

Practice is paying off. Getting to mastery is not a straight line, and I am quite sure there will be a few face-plants still left in my future, but the satisfaction of making something exactly as envisioned? Priceless!

Monday, February 12, 2018

Always Learning

I sat in the hot tub this morning in a light misty rain, thinking of the leather bag project I am working on now. Time passed, suddenly a half hour was gone, and my tea was getting cold! I do love that kind of time, and the "making-in-my-mind" as I walk through the steps of the next thing. It occurred to me to wonder what people think about when they are not makers. Do they sit and ponder the world's problems, their own problems, their children's problems? Do they daydream about the next vacation, or the list of chores or errands? What occupies their thoughts, the way that making occupies mine??

I have been busy making. Christmas and gift giving necessitates that photos not be published before the gift is given, of course, and then, suddenly it's February and I have not posted here for many months! So herewith, in no particular order:

I went to Penland in August, to take a class in leather working:

The woman who taught the class makes cowboy boots (!) but the class itself was about inlay and overlay in leather, and I learned a lot! I think I might have been the absolute worst student, in terms of technique, but practice will make it better. I do love the samples I made, warts and all, and I am employing some of the techniques in my bags combining textiles and leather.

Next up is a bag I made for my friend Mollie, using her handwoven printed and stitched cloth for the front pocket. She and I have been weaving friends and personal friends for over 40 years, and we can still talk for hours on end whenever we meet. So, for her birthday, she got a bag! I think she likes it :).

There has been some weaving: two silk fabrics, the first is a scarf because it was a failure for it's intended purpose (part of a jacket, it shrunk too much in width). It makes a great scarf though, so no harm, no foul. The second is the fabric that ended up as part of that jacket, and it is a total success. Also silk, that jacket is in the process of being sewn up now.

Then there are the Christmas presents:

Small bags and a keychain (with a cardwoven tab!), way cute.

And a carry-on size backpack for my son. This was the major project, many hours and many things learned. It works! he's already traveled with it at least once. I love making stuff people will use...

This year, for our Christmas travel, we took the train across half of the country. What a treat! travel was at a human pace, not frantic, with no TSA-driven restrictions, and a leisurely 2 days and nights of scenery slowly ambled by. Meals were excellent, and I lost count of the bald eagles I saw while knitting, sipping a drink, and watching the world out the window from a cosy rocking train. Such a delightful way to get from here to there...this will not be the last time!

Last, coming up in June is the annual meeting for WARP. In September, I met with the organizer to see the venue and help set up the activities around the meeting site, which will be in Decorah, Iowa. As part of the festivities, we will have a reception and tour of Vesterheim, the Norwegian American Museum. We got a sneak peek in the vaults of textiles stored there and oh! be still my heart, I was even allowed to take some photographs:

There will be more textile posts of pieces from the collection, but I'm here to tell you: if you are a textile enthusiast of any stripe, and happen to be in Northeast Iowa, a stop in Decorah at Vesterheim is a must! The range of textiles is astounding, from rugs and tapestries to woven and knitted clothing, bands and mittens, handmade leather shoes! and stockings, socks and gloves. There is always something I can learn from textiles, and to be able to examine them up close? with a docent to put them in cultural context? Brilliant! I can't wait for the annual meeting and this tour!!!

I have been busy making. Christmas and gift giving necessitates that photos not be published before the gift is given, of course, and then, suddenly it's February and I have not posted here for many months! So herewith, in no particular order:

I went to Penland in August, to take a class in leather working:

The woman who taught the class makes cowboy boots (!) but the class itself was about inlay and overlay in leather, and I learned a lot! I think I might have been the absolute worst student, in terms of technique, but practice will make it better. I do love the samples I made, warts and all, and I am employing some of the techniques in my bags combining textiles and leather.

Next up is a bag I made for my friend Mollie, using her handwoven printed and stitched cloth for the front pocket. She and I have been weaving friends and personal friends for over 40 years, and we can still talk for hours on end whenever we meet. So, for her birthday, she got a bag! I think she likes it :).

There has been some weaving: two silk fabrics, the first is a scarf because it was a failure for it's intended purpose (part of a jacket, it shrunk too much in width). It makes a great scarf though, so no harm, no foul. The second is the fabric that ended up as part of that jacket, and it is a total success. Also silk, that jacket is in the process of being sewn up now.

Then there are the Christmas presents:

Small bags and a keychain (with a cardwoven tab!), way cute.

And a carry-on size backpack for my son. This was the major project, many hours and many things learned. It works! he's already traveled with it at least once. I love making stuff people will use...

This year, for our Christmas travel, we took the train across half of the country. What a treat! travel was at a human pace, not frantic, with no TSA-driven restrictions, and a leisurely 2 days and nights of scenery slowly ambled by. Meals were excellent, and I lost count of the bald eagles I saw while knitting, sipping a drink, and watching the world out the window from a cosy rocking train. Such a delightful way to get from here to there...this will not be the last time!

Last, coming up in June is the annual meeting for WARP. In September, I met with the organizer to see the venue and help set up the activities around the meeting site, which will be in Decorah, Iowa. As part of the festivities, we will have a reception and tour of Vesterheim, the Norwegian American Museum. We got a sneak peek in the vaults of textiles stored there and oh! be still my heart, I was even allowed to take some photographs:

There will be more textile posts of pieces from the collection, but I'm here to tell you: if you are a textile enthusiast of any stripe, and happen to be in Northeast Iowa, a stop in Decorah at Vesterheim is a must! The range of textiles is astounding, from rugs and tapestries to woven and knitted clothing, bands and mittens, handmade leather shoes! and stockings, socks and gloves. There is always something I can learn from textiles, and to be able to examine them up close? with a docent to put them in cultural context? Brilliant! I can't wait for the annual meeting and this tour!!!

Thursday, October 12, 2017

Reading, Again!

First up! Last week's post garnered more than 2! comments, so I have turned to a random number generator. Thanks to everyone for commenting, and I truly do recommend this book if you have any inclination to buy it or put it on your gift list!

Between number 1 and 15 the generator picked...#1! Congratualtions jeekeehoo! You'll need to sned me an address: sara at sara lamb dot com (remove all spaces, etc., yadda yadda).

Further reading: I have cleared out some magazine subscriptions that no longer served me, and found a few new ones. Below are the ones I currently take. For fiber and serious weaving:

Selvedge, for inspiration, Vav for inspiration and weaving information, Fiber Art Now for aspiration, Piecework and SpinOff for tips, tricks, how-to's and news of my community.

Newer more self-published magazines, whose layout, content and graphic presence are clean, readable and inspiring:

Taproot, not a craft magazine per se, but has crafts, gardening/farming, herbs, and thoughtful essays, with a new compilation book of crafts and things to make from their first several years' of publication, KnitWit, and Making, both published by crafters/knitters, both with a clean look and some inspiring work.

and last, if you cook (who doesn't?) my new favorite foody mag:

The new project by Christopher Kimball, formerly Cook's Magazine and America's Test Kitchen, now out on his own with this eminently readable and eatable offering!

Most of these are also available at newsstands and good book stores, so you can check them out before subscribing. Or...order a single issue from their websites.

I depend on publications for news and inspiration, and (truth in advertising here) have had work published in some of these over the years. They are mostly daydream publications for me, rather than how-to: I am inspired by the work of others, and sometimes their solutions solve my problems. They are not too "thinky", and do not try too hard to intellectualize what is, for me, and visual and tactile world. Studio work can be lonely and isolated: the people between these pages help me feel connected to the people inhabiting this little corner of the fiber world.

Between number 1 and 15 the generator picked...#1! Congratualtions jeekeehoo! You'll need to sned me an address: sara at sara lamb dot com (remove all spaces, etc., yadda yadda).

Further reading: I have cleared out some magazine subscriptions that no longer served me, and found a few new ones. Below are the ones I currently take. For fiber and serious weaving:

Selvedge, for inspiration, Vav for inspiration and weaving information, Fiber Art Now for aspiration, Piecework and SpinOff for tips, tricks, how-to's and news of my community.

Newer more self-published magazines, whose layout, content and graphic presence are clean, readable and inspiring:

Taproot, not a craft magazine per se, but has crafts, gardening/farming, herbs, and thoughtful essays, with a new compilation book of crafts and things to make from their first several years' of publication, KnitWit, and Making, both published by crafters/knitters, both with a clean look and some inspiring work.

and last, if you cook (who doesn't?) my new favorite foody mag:

The new project by Christopher Kimball, formerly Cook's Magazine and America's Test Kitchen, now out on his own with this eminently readable and eatable offering!

Most of these are also available at newsstands and good book stores, so you can check them out before subscribing. Or...order a single issue from their websites.

I depend on publications for news and inspiration, and (truth in advertising here) have had work published in some of these over the years. They are mostly daydream publications for me, rather than how-to: I am inspired by the work of others, and sometimes their solutions solve my problems. They are not too "thinky", and do not try too hard to intellectualize what is, for me, and visual and tactile world. Studio work can be lonely and isolated: the people between these pages help me feel connected to the people inhabiting this little corner of the fiber world.

Tuesday, October 03, 2017

Happy Spinning and Weaving Week!

I have been on a tear in the studio. I have things to do! Things to make! A backlog of ideas which creates a frenzy of activity which breeds more ideas! Happily, the ideas have all been things I could make while using up the stash. Well mostly. Well, OK, I bought some stuff.

But really! Fun! Things! :)

In the past few months I have been on the road more than I have been home. It was mostly just a convergence of events, some I had scheduled, and some beyond my control. So...I have been gone.

Being away from the studio does not mean I had no projects at hand...they were just handwork though, spindles, knitting, some small weaving. Sanity was preserved by these small things, but ...I missed my loom! I missed my spinning wheels! There was very little leather stabbing.

All's well now.

In the many weeks of travel, I also read. I was sent this new book:

It is always fun to read a weaving book (for me) and when the book is full of surprises, more fun! While Liz has written this as a series of projects for the home, and for the rigid heddle loom, the information presented and the projects would make an excellent workbook for any beginning weaver.

There is information about yarns: cotton, wools, linen, hemp and synthetics, yarn choices, setts, many weaving tips and tons of close up photos of the weaving process. Throughout the book are tips on choosing colors, fixing mistakes, and finishing options. A longtime weaver herself, Liz uses common weaving terms, and defines them, so the new weaver is introduced to the jargon she will need when consulting other weavers or weaving books. The projects are practical and beautiful, something any weaver would be proud to use and give.

The last chapter is an in depth discussion, with many photos, of warping the rigid heddle loom in several ways. The process is easily mastered with a RH loom, and all the learning is transferable should one wish to progress to a table or floor loom at any time.

The RH loom is a fabulous entry-level learning tool, takes up much less space than most table looms, or a small floor loom, and is also usually fold-able or easily stored away. An RH loom is quiet enough to be used in a room with other people, without interfering with movies or music, or the sound of the surf on the sands! I resisted using RH looms for a long time, and now, especially this summer, I am so glad I was able to use a Cricket loom while away from home. I did not have to stop weaving, just because I was traveling.

So, grab the book, if you can, and "ta-da!" I have this copy to give away! Just leave a comment that you'd like to receive it, and if two of you reply, I'll flip a coin! If more than two reply, we'll use a random number generator. Be sure to leave me contact info if case you win!

But really! Fun! Things! :)

In the past few months I have been on the road more than I have been home. It was mostly just a convergence of events, some I had scheduled, and some beyond my control. So...I have been gone.

Being away from the studio does not mean I had no projects at hand...they were just handwork though, spindles, knitting, some small weaving. Sanity was preserved by these small things, but ...I missed my loom! I missed my spinning wheels! There was very little leather stabbing.

All's well now.

In the many weeks of travel, I also read. I was sent this new book:

It is always fun to read a weaving book (for me) and when the book is full of surprises, more fun! While Liz has written this as a series of projects for the home, and for the rigid heddle loom, the information presented and the projects would make an excellent workbook for any beginning weaver.

There is information about yarns: cotton, wools, linen, hemp and synthetics, yarn choices, setts, many weaving tips and tons of close up photos of the weaving process. Throughout the book are tips on choosing colors, fixing mistakes, and finishing options. A longtime weaver herself, Liz uses common weaving terms, and defines them, so the new weaver is introduced to the jargon she will need when consulting other weavers or weaving books. The projects are practical and beautiful, something any weaver would be proud to use and give.

The last chapter is an in depth discussion, with many photos, of warping the rigid heddle loom in several ways. The process is easily mastered with a RH loom, and all the learning is transferable should one wish to progress to a table or floor loom at any time.

The RH loom is a fabulous entry-level learning tool, takes up much less space than most table looms, or a small floor loom, and is also usually fold-able or easily stored away. An RH loom is quiet enough to be used in a room with other people, without interfering with movies or music, or the sound of the surf on the sands! I resisted using RH looms for a long time, and now, especially this summer, I am so glad I was able to use a Cricket loom while away from home. I did not have to stop weaving, just because I was traveling.

So, grab the book, if you can, and "ta-da!" I have this copy to give away! Just leave a comment that you'd like to receive it, and if two of you reply, I'll flip a coin! If more than two reply, we'll use a random number generator. Be sure to leave me contact info if case you win!